Cathodic protection by impressed current is only used on ships’ hulls and fixed structures, whereas galvanic anodes are usually used for all types of structures and are directly attached.

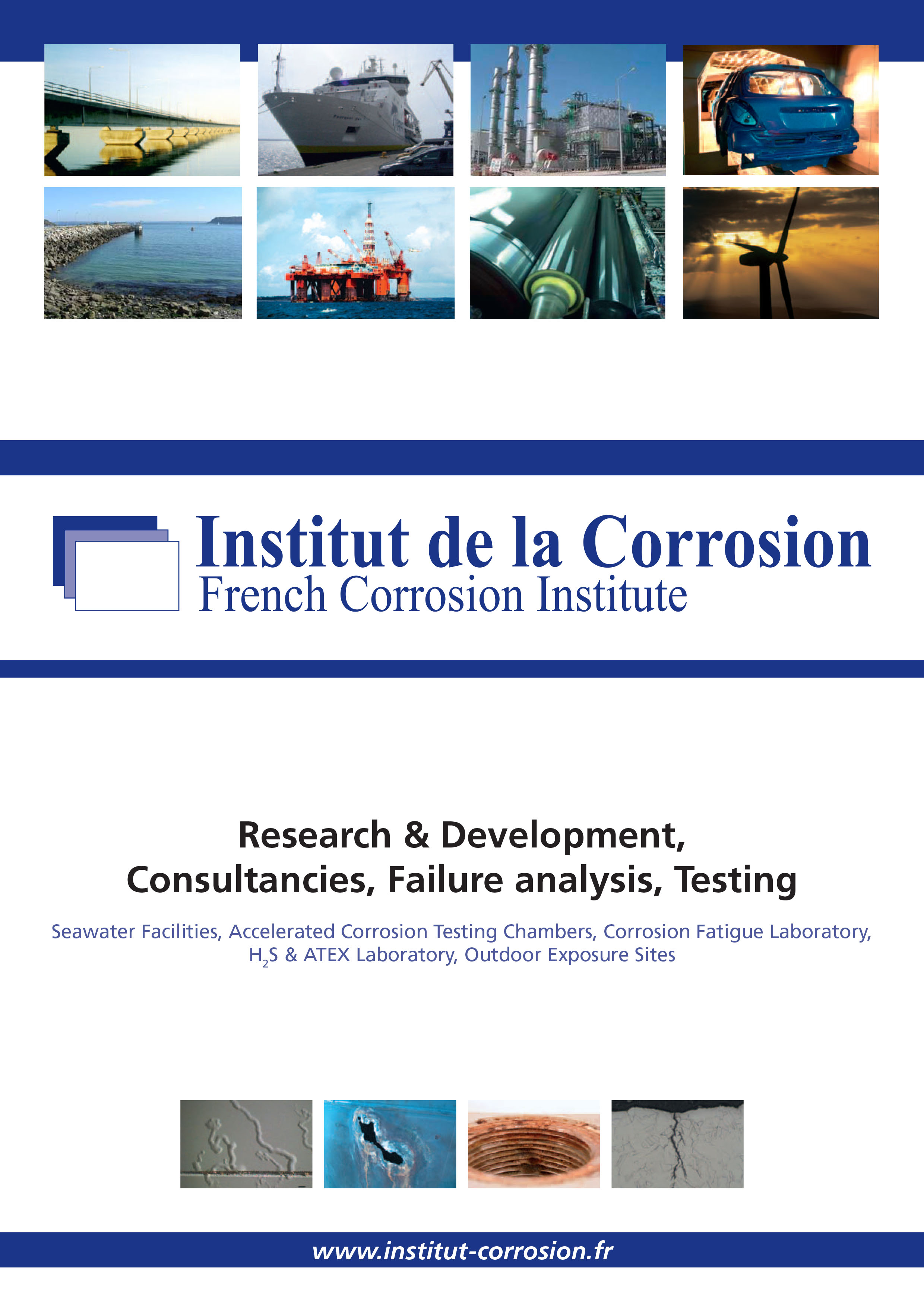

The current density which is necessary to obtain cathodic protection depends mainly on the environment surrounding the structure. Chart 2 gives orders of magnitude of this current density for non-coated steel. The presence of coating will decrease this current density, because only part of the steel is in contact with water (notion of insulation resistance or degradation coefficient).

It should be noted that steel immersed in sea water gets covered, because of cathodic protection (local pH increase), with a calcareous deposit. This deposit slightly decreases the current density required for protection, after a few months of operation.

Table 2 : Order of magnitude of the current density to protect a non alloy, not coated carbon steel structure.

| ENVIRONMENT | CURRENT DENSITY mA.m²) |

|---|---|

| Cold, stagnant fresh water | 20 |

| Warm fresh water | 150 |

| Cold, agitated sea water | 220 |

| Warm sea water | 60 |

| Sea-beds | 20 |

The number and the location of the anodes are determined by simple rules or numerical calculation, especially if the structure has a complex form.